Recently, more than sixty well-known textile manufacturers demonstrated their interest in the new Global Textile Scheme (GTS). GTS has been under development for almost a year by a group of ERP system manufacturers, association experts and brand manufacturers. In a webinar lasting a good hour, members of the GTS initiative clarified the standardisation of product data transmission in various use cases. The aim is to establish automated data exchange using a standardised language along the entire textile supply chain.

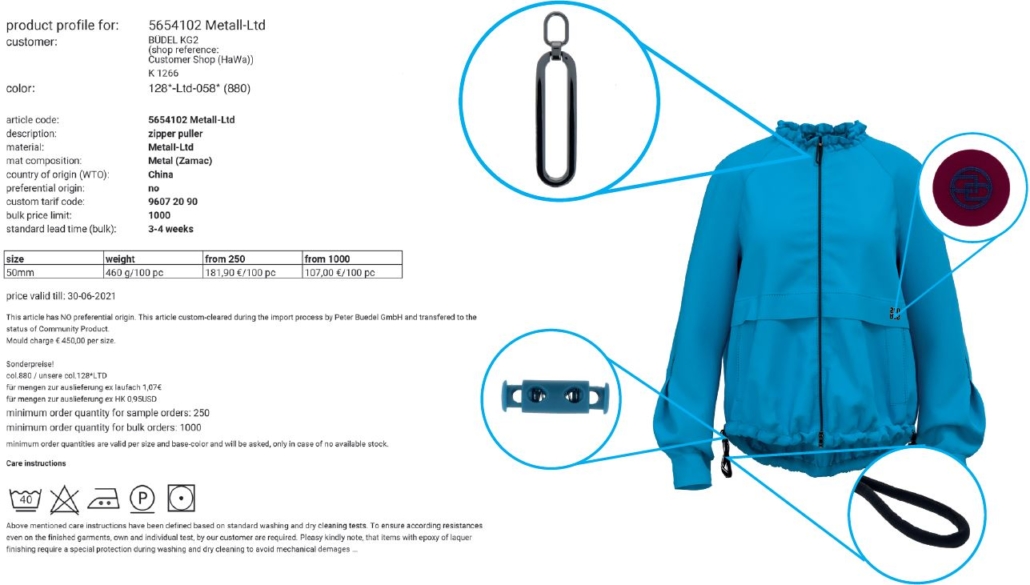

By standardising information and automating business paperwork, electronic data interchange (EDI) has been saving retailers and suppliers a lot of time and money for almost forty years. The upstream sections of the supply chain, however, have so far been completely excluded from these blessings. The subtle differences in materials such as fabrics, thread, buttons and buckles appeared too diverse and individually defined. Yet it is precisely this diversity that offers enormous potential for efficiency. The greater the manual effort for an exact description, the greater the susceptibility to errors, which in the worst consequence leads to the consumer not finding the product in question.

High data quality along the entire textile chain

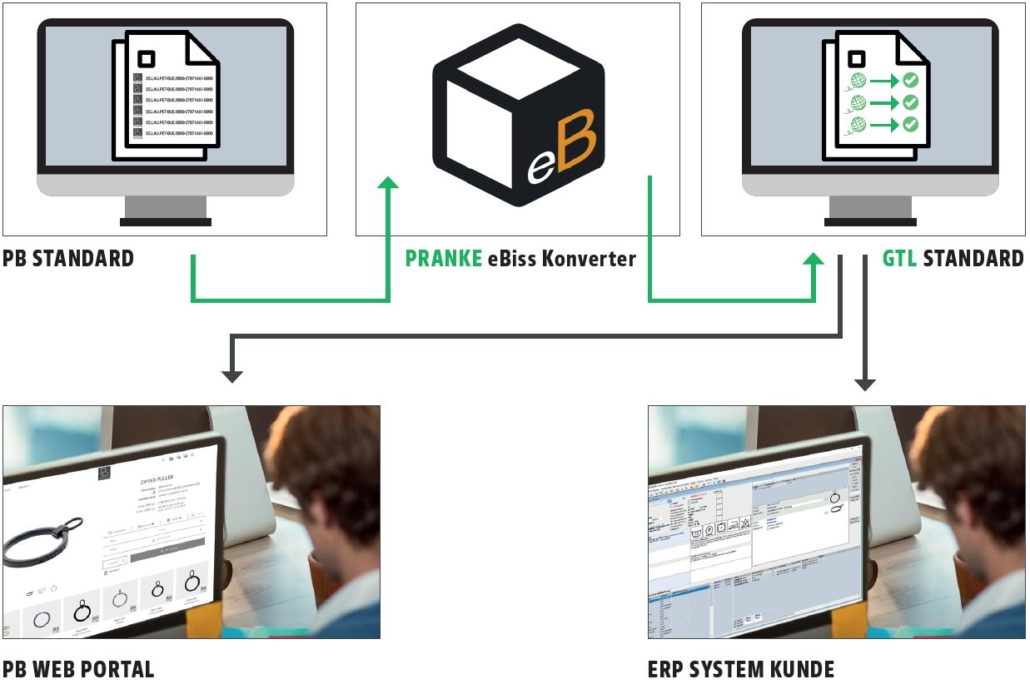

GTS now demonstrates that it is possible. With decades of expertise in the textile industry and the corresponding networking behind him, the initiator Andreas Schneider developed the GTS Language together with forward-looking textile manufacturers, fashion brands and major IT producers. This coded catalogue allows users to communicate in their respective mother tongues. In order to digitise this catalogue and thus create the prerequisite for automation, Schneider asked Pranke GmbH to set up a technical infrastructure. Pranke has been established as an EDI expert in the industry for decades. Within a few months, a high-performance platform was created.

Suppliers can use it to track the demand for their products live, so to speak, plan better and produce closer to demand. The customer saves on short-quantity surcharges and delivery times. He benefits from unprecedented data quality because he can import all product-describing master data into his system – if his supplier is connected to GTS.

Schneider and his colleagues were thus able to demonstrate to the webinar participants not only that GTS provides the upstream stage of the textile supply chain, after integration into the existing EDI processes, with the secure, fast, correct and cost-saving building block to digitise and automate the chain from start to finish. In fact, GTS already offers the possibility of documenting the materials used, as is increasingly demanded by politicians with a view to sustainability and the ethical use of resources, and will soon be made indispensable by law.

Meanwhile, the creators of GTS are not sitting back. Andreas Schneider and the other organisers of the webinar, Intex EDV-Software GmbH, Impuls AG, Pohl Softwear GmbH and textdata software gmbh, invite interested companies to join the initiative and participate in its further development.

Experience the Webinar “GTS” on You Tube (in German).

Or read the Peter Büdel USER STORY of exceeding expectations in the GTS eBiss project.

Peter Büdel GmbH

Peter Büdel GmbH